Edblad

By being able to offer customers the possibility to make an exchange directly in the return process without needing to place a new order, Stellar Equipment has increased their repurchase rate by 20%. The digitization of returns and return reason codes has also enabled Stellar to quickly identify items or customers with deviation in return rates and promptly take action to assist customers in finding the right solution. This has resulted in their NPS increasing by 10%

Stellar Equioment’s exchange process was an administrative burden both internally and for their end consumers. Their main challenge was that customers were hesitant to place a new order for the item they wanted to exchange until they saw the money refunded to their account. The internal process for handling the returns and refunds was too manual and time consuming. This created an uncertainty among the customers which led to numerous inquiries about the handling process and a lot of transactions were lost due to the complexity in the exchange process.

Before using Inretrn, our exchange process was loaded with heavy administrative tasks. This put a strain on our team and our customers, and often led to missed business opportunities because of the long wait times.

Ted Bergner, CTO

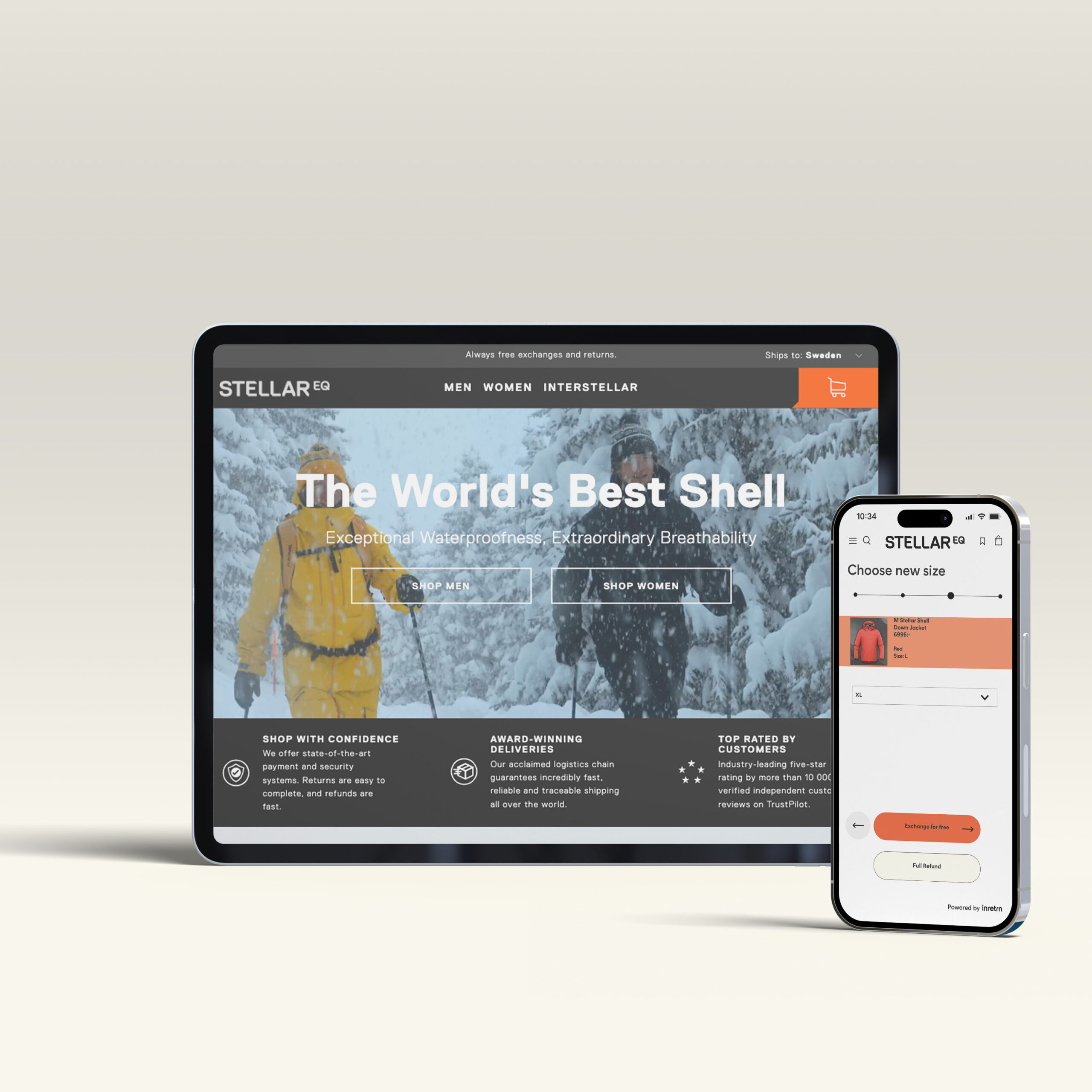

After thoroughly evaluating several different solutions, Stellar Equipment selected Inretrn as their returns management platform.

In march 2020, Stellar Equipment initiated their collaboration with Inretrn and began the implementation of the new, intelligent digital return management platform. The project was carried out in collaboration together with Navipro and Centra, and the implementation of a digital returns platform went according to plan, staying within the set timeframe and maintained close dialogue for a smooth onboarding.

After evaluating various solutions available in the market, we discovered Inretrn. We were notably impressed by Inretrn’s proven expertise and extensive background in operational logistics.

Ted Bergner, CTO

After implementing the return management platform, Stellar gained entirely new capabilities to swiftly identify deviations in return data. By pinpointing high return rates, Stellar managed to decrease its return rate by -5%. More importantly, they could understand the reasons behind exchanges and returns. Leveraging data from the reason codes, Stellar actively worked on countering returns by enhancing their product descriptions, size guides, and the way they present their products.

With the platform, they can now communicate with customers in entirely different ways than before. The ability to engage with customers throughout the return process, reassuring them that everything is proceeding as expected, significantly reduced customer service inquiries. The time customer service previously spent on return-related matters can now be dedicated to value-added tasks and development.

“Our greatest challenge was managing complex return processes for export markets, which often left customers frustrated by the difficulty and lengthy duration of making a return. The process has now become much smoother, and we have not received any complaints from customers in these markets. Furthermore, there has been a substantial reduction in internal administration for both our customer service and warehouse teams”

– Ted Bergner, CTO